- Technology - Physik Instrumente (PI) GmbH & Co. KG

Laser Drilling: Quick and Accurate Positioning of the Laser Beam and Workpiece with a Single Controller Strategy

Whether in the production of fuel injection nozzles, cooling holes for aerospace components, or microvias in printed circuit boards (PCBs) - laser drilling continues to find new applications. A key driver is the trend toward miniaturization. Laser drilling machines must be able to achieve ever-higher accuracies down to the submicron range.

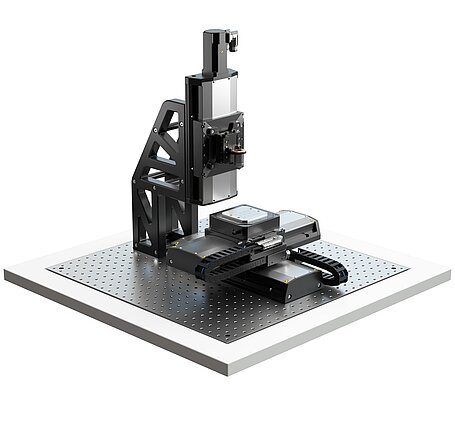

The concept consists of long travel XY positioning stages for workpiece positioning, highly dynamic Z axis for laser focusing, and the choice of either enhancing beam or workpiece positioning via the use of piezo motion. PI’s range of ACS servo controls and PI’s piezo drives, plus specific laser control options enhance the throughput and precision during the process. Both are essential when drilling deep holes with high aspect ratios, whilst controlling heat affected zones (HAZ).

Precise Positioning of Workpieces

For the movement and precise positioning of workpieces under the laser, PI offers modular hybrid motion systems. Servo driven ball screw or direct driven precise linear motion stages provide longer travel ranges, while highly stiff piezo positioners can manage precise fine adjustments. These operate with nanometer accuracy and can move workpieces precisely to create challenging complex geometries, such as multi-faceted shapes with specific wall constraints. Step-and-settle occurs within mere milliseconds, while the linear encoder feedback, provides nanometer resolution, enables maximum precision.

The piezo positioners use the reverse piezo effect. When a voltage is applied the piezoelectric ceramics generate movements in the nanometer range. These movements are highly dynamic and have the highest repeatability. The PICMA piezo elements from PI Ceramic used for this purpose are wear-free and position with the same accuracy as when first installed, even after billions of cycles.

Moving the Laser Focus

For vertical positioning of the laser focus, PI provides the V-308, a highly dynamic and voice coil-driven solution with travel ranges of up to 8 mm. This enables drilling of holes with large aspect ratios and vertical edges, even in thick workpieces. The ACS microcontroller directly coordinates the Z movement with the positioning stage axes. All drives can be controlled via the controller in closed-loop mode. As the ACS controller provides the option for CNC G-code scripting this universal programing approach can be used for programming as well as the native powerful ACS language. The use of EtherCAT provides simplified engineering and commissioning. In addition, the use of Dynamic Digital Linearization (DDL) a piezo control algorithm enhances tracking performance in high-frequency applications, optimizing process quality and productivity.

Physik Instrumente (PI Group) in Brief

The PI Group with headquarters in Karlsruhe, Germany, is the market and technology leader for high-precision positioning technology and piezo applications in the market segments Industrial Automation, Semiconductor Industry, Photonics, and Microscopy & Life Sciences. In close cooperation with international customers, PI's approximately 1,500 specialists have been continuously pushing the boundaries of what is technically possible for more than 50 years. Various drive technologies, internally developed sensor technology, electronics, and control technology provide the basis for this. PI’s portfolio ranges from components to subsystems, to tailor-made complete solutions. 508 granted and pending patents underline the company's claim to leadership in the fields of precision positioning and piezo technology. PI operates on a global scale, with nine production sites in Europe, North America, and Asia, as well as sixteen sales and service subsidiaries.