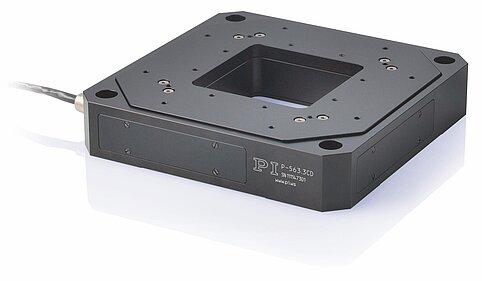

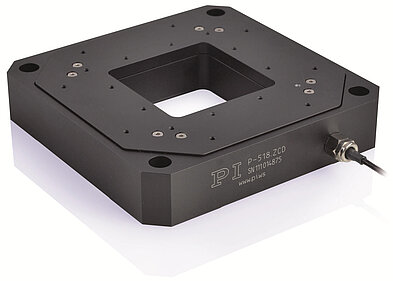

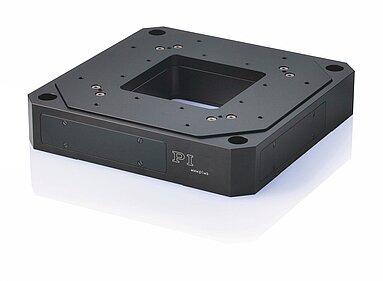

Multi-Axis Piezo Flexure Stages

PI’s multi-axis piezo flexure stages allow positioning and scanning with sub-nanometer precision in up to 6 axes, including tip, tilt and yaw motion. Versions range from most compact cube design to large aperture and low profile.

XYZ Scanners are all-rounders in positioning technology. Applications include sample adjustment, technology, optical metrology, fiber positioning and photonics, as well as atomic force microscopy.

All piezo nanopositioning systems are factory-calibrated and delivered with measurement log.