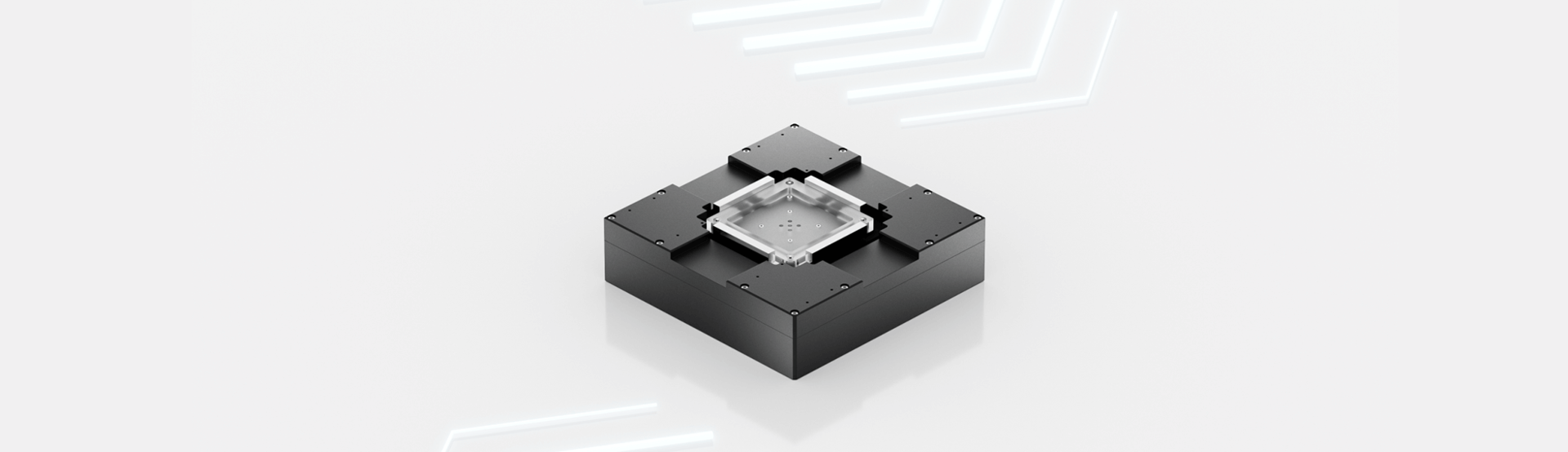

Magnetic Levitation

The Future of High-Precision Motion Begins with Contactless Technology

With magnetic levitation, we are expanding our existing portfolio with a technology, which combines maximum precision, absolute cleanliness, and pioneering controllability. Contactless bearings and active control in six degrees of freedom with resolutions down to the picometer range are setting new standards in positioning technology.

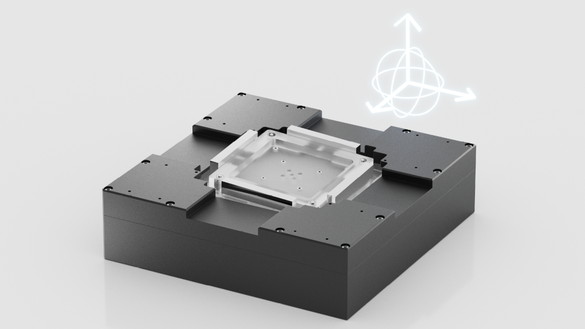

Picometer Resolution

Picometer Resolution

The combination of high-precision sensor and drive technologies with intelligent firmware and high-performance controller solutions enables contactless, magnetic guidance and ensures maximum positioning accuracy with resolutions of up to 200 picometers.

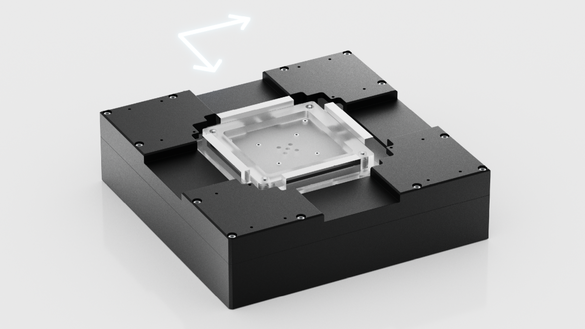

Active Control in Six Degrees of Freedom

Active Control in Six Degrees of Freedom

The active control in six degrees of freedom makes it possible to set guide characteristics in all directions. Motion can be freely defined directly in the positioning system, including correction functions such as focusing or tilt adjustment.

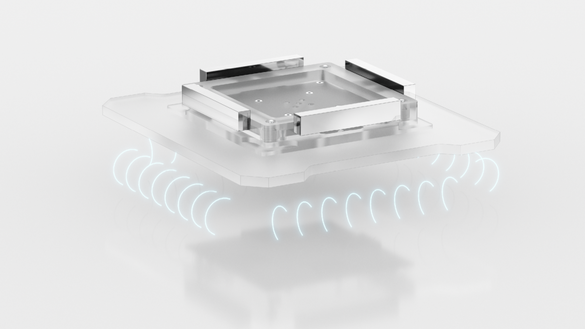

Contactless Operation

Contactless Operation

Friction-free guides without rolling bodies that do not require lubrication or airflow ensure maximum precision of motion and positioning throughout their entire lifetime and enable the use in cleanrooms and vacuum environments.

What makes magnetic levitation so unique is the contactless bearing we can realize within our mechanical system.

Dr. Christian Rudolf, Director Technology Center Drives & Systems

Magnetic Levitation: Today’s Technology, Tomorrow’s Potential

MagLev technology has been realized and proven effective for tactile imaging processes. Our team is currently working to realizing this technology for additional applications in semiconductor inspection/lithography and precision manufacturing at the subnanometer scale—focusing on higher payloads, larger travel ranges, and accelerated dynamics.

Take your application into the picometer range! Talk to our engineers about your individual requirements.

Contact us today!