Hermetic Sealing of Electronic Components Using Laser Welding

Complex Path Contouring – Synchronized Laser Control – High Throughput

When confronted with health problems, medical technology today makes it possible for implants, for example pacemakers or insulin pumps, to perform important functions. Such implants are highly complex systems consisting of electrical and electronic components. Hermetic sealing, which keeps the microsystem and the surrounding tissue reliably separated from each other, is necessary for safe and reliable use in the human body. Components depend on hermetic sealing in order for them to function properly and reliably in other industries as well, for example sensors and electronics in the semiconductor industry or battery encasings need to be protected against vapor or foreign particles.

Laser welding is one method used for sealing. For this purpose, the laser spot is focused on the rotating workpiece. In order to achieve a uniformly high seam quality, the size of the laser spot must be maintained by keeping the distance between the laser and the workpiece the same during welding. In addition, the laser beam must must hit the surface of the workpiece at the correct angle. Holding or alignment errors of the workpiece must also be considered and corrected by the control of the laser welding path.

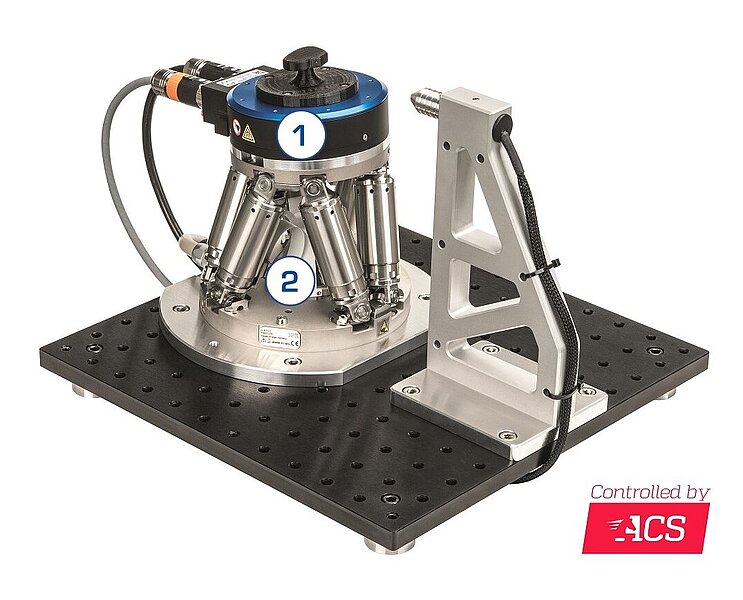

Hexapods, which can move in six degrees of freedom and allow for the definition of reference systems for workpiece and tool ("work", "tool" coordinate systems), can perform all these tasks reliably.

Key Features of the Positioning Solution

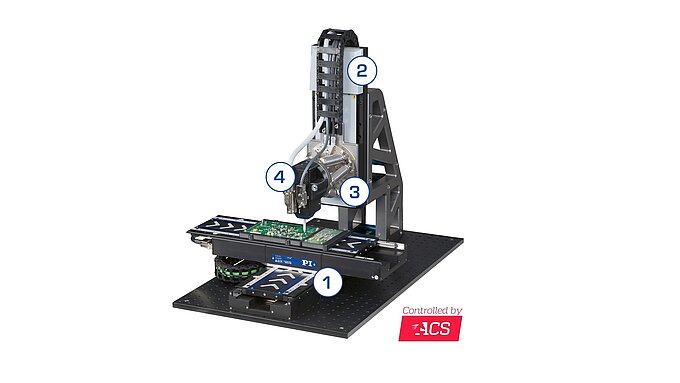

Orientation of electronic component according to the required laser weld path:

- High velocities and accelerations due to PIMag® magnetic direct drives

- Flexible adaptation of drive force and dimensions due to in-house developed ironless torque motors

- Smooth and precision operation w/o cogging

- Highly accurate and repeatable rotation without backlash

>> V-610

Maintaining laser distance, laser angle, and laser spot size for constant seam weld quality:

- Parallel kinematic hexapod

- Six degrees of freedom

- Freely definable center of rotation for both tool and work piece coordinate systems

- Precision tracking of complex motion profiles

>> H-811.I2

- ACS SPiiPlus EtherCAT® network motion controllers and drive modules for optimum synchronization of the axes and simultaneous control of the laser:

>> ACS SPiiPlusES Multi-Axis EtherCAT® Controller

>> ACS UDMnt EtherCAT® Drive Module - Laser Control Module for controlling the laser source directly with full synchronization to the motion path

>> ACS LCM - Hexapod Controller with EtherCAT® provides connectivity to any standard EtherCAT® platform

>> C-887.53x