Alignment is crucial for effectiveness and performance in SiPh production. The industry has come a long way from manual processes to intelligent automation of photonics testing, assembly, and packaging. As the alignment of optics, fiber arrays, etc is the most time-consuming production step, new automated solutions improve yield, time-to-market, cost reduction, and scaling production volumes.

Learn moreMastering Precision

The Evolution of Photonics Alignment Techniques from Manual to Algorithm-Assisted, Automated Systems

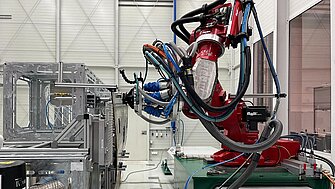

Advances in Aircraft Construction

Hexapod Enables Highly Dynamic 6-D Compensation Kinematic for Robots

· Stefan Vorndran

Physik Instrumente developed a high-performance 6-DOF hexapod motion and positioning system for highly dynamic compensation kinematics in aircraft construction. The project's goal was to enhance the processing and sealing precision of CFRP-components in resin transfer molding manufacturing processes, while also reducing manufacturing times and process costs.

Learn moreSome Like it Hot

How PI Is Helping to Unlock the Sun's Secrets

· Arne Bramigk · Markus Wiederspahn

The Solar Orbiter space probe begun its journey in February 2020. Also on board: A tip/tilt unit from PI for the secondary mirror of one of the central experiments, the Polarimetric and Helioseismic Imager (PHI).

Learn moreThe Missing Link

A Breakthrough in Automated Assembly of Photonic Integrated Circuits

· Markus Wiederspahn

Assembly and packaging of photonic devices requires highly efficient production systems. Alignment is one of the biggest cost factors when producing these components since it is repeated several times in the production process. PI's revolutionary fast alignment technology has been unsurpassed for these challenges.

Learn moreSmart Vaccine Patch Production with Piezo Elements

Fight Against COVID-19

· Dr. Annemarie Oesterle

In the wake of the global COVID-19 pandemic, modern vaccination technologies are gaining importance as they promise to protect the world population from future pandemics. Vaccine patches are one of these next generation applications and piezo components or actuators can be used to precisely dispense tiniest droplets on the microneedles.

Learn moreUltrasonic Metering in Intensive Care Devices

Fight Against COVID-19

· Dr. Annemarie Oesterle

Viruses and other infections particularly affect people with pre-existing conditions such as renal or cardiovascular diseases. In regard to the treatment and therapy of such illnesses, the demands on the medical devices used are ever increasing. Piezo technology offers various possibilities to improve them: Using piezo transducers, for example, makes intensive care devices such as infusion systems smarter and facilitates vital patient monitoring.

Learn morePiezo Technology for Medical Ventilators and Nebulizers

Fight Against COVID-19

· Dr. Annemarie Oesterle

Chronic respiratory diseases like mucoviscidosis, asthma or chronic obstructive pulmonary disease (COPD) but also bronchitis, influenza and lung diseases related to COVID-19 require extensive medical treatment. Medical ventilators and nebulizers have a significant part in improving patients’ clinical condition and treating their illnesses. Piezo-driven devices offer high precision and efficiency as well as hygienic advantages.

Learn moreHow an Industrial Safety Concept Can Be Combined with a Hexapod

Finger, hand, or body protection in automated production processes

· Doris Knauer

The integration of a barrier-free safety concept into the control circuit of the hexapod, e.g. of a PILZ safety light curtain, ensures finger, hand, and body protection depending on the required safety level.

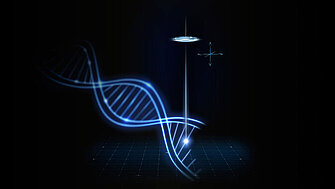

Learn moreHigh Dynamic and Precision in All Three Directions in Space: Positioning Systems for Genome Sequencing

Fight Against COVID-19

· Dr. Thomas Bocher · Markus Wiederspahn

The Sequencing-by-Synthesis method, also known as Solexa-Illumina-method, is the most widespread method among all Next-Generation-Sequencing methods (NGS). It was used to identify the RNA fingerprint of the SARS-CoV-2 virus in January 2020 in a research institute in Wuhan. Since then, this RNA fingerprint measurement has frequently been repeated in research institutes all over the world. And today this NGS method is used worldwide day-by-day to continuously monitor the SARS-CoV-2 virus for mutations. Sub-systems for motion and positioning of imaging optics and flow cells play a decisive role in this method.

Learn morePiezo Ceramics Enable Precise Liquid Handling for in Vitro Diagnostics

Fight Against COVID-19

· Dr. Annemarie Oesterle

In vitro diagnostics (IVD) opens up numerous possibilities for early diagnosis and detection of diseases. The requirements for fluid handling in IVD devices are extremely demanding: very small quantities of fluids with different properties must be dosed or moved with high precision. Piezoelectric components and actuators perform these tasks.

Learn more